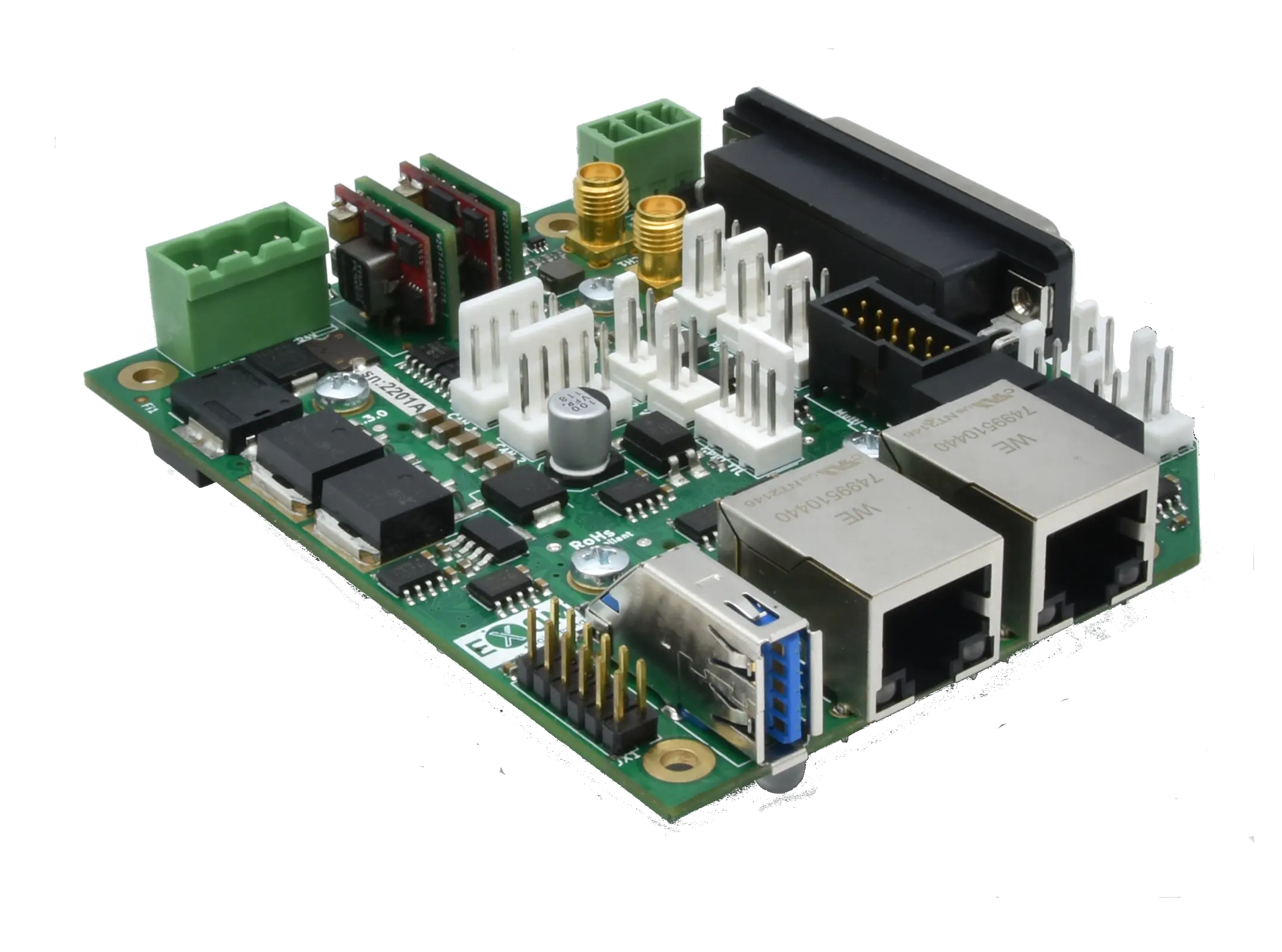

Hardware, Firmware & Software

From start to end, we control every aspect of the development

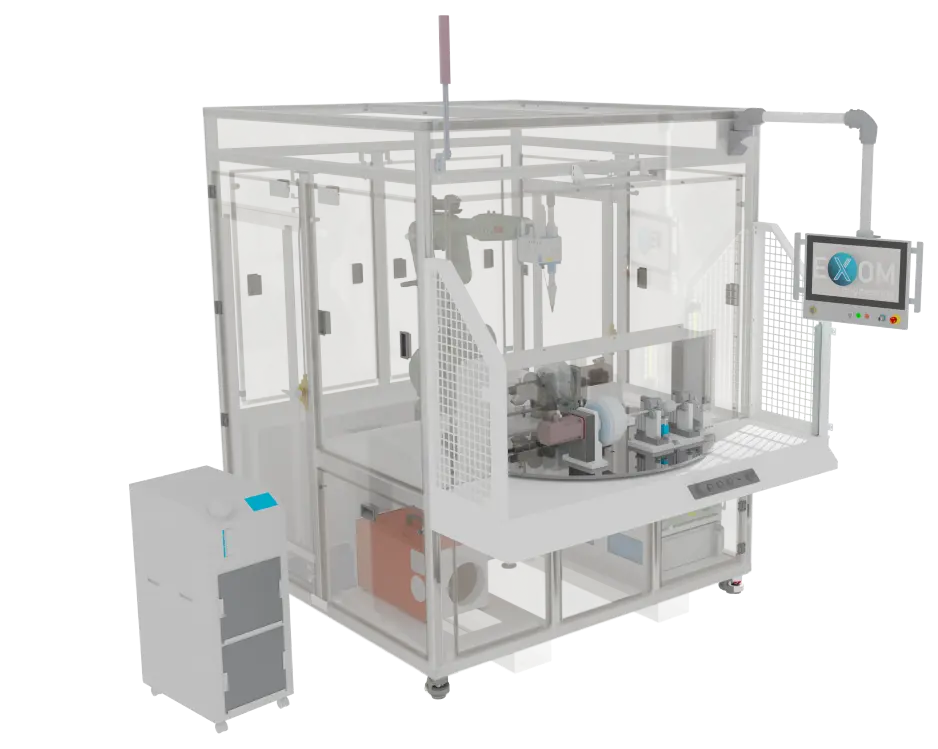

Control and Automation

Process development with the best fitting solutions to your requirements

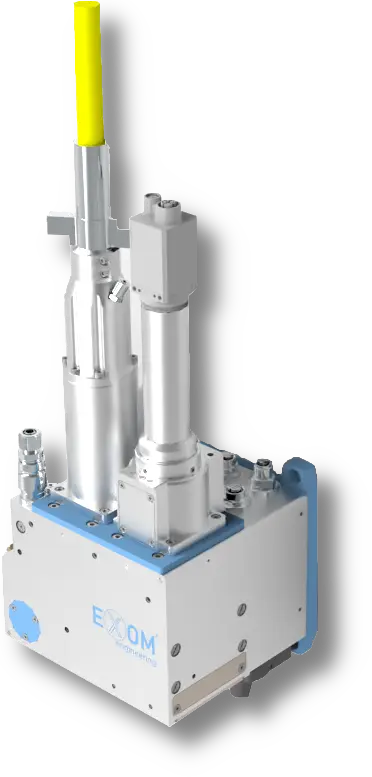

Introducing the Laser Head - Wobbwelder SO1

Whether you're working with stainless steel, aluminum, copper, or other high reflective metals, our machine delivers consistent results, surpassing traditional welding methods.

- Laser welding of material including high reflective metals

- Surface treatment

- Laser processing of coatings

Let us know about your projects and ideas, we will find the right solution.

We develop our core technology in house, staying flexible to customer demands and reducing our dependency to third-party technological solutions.

Contact us!Stay on the loop. See our latest news and blogs.

STELA Project: Advancing Intelligent Manufacturing through Laser Technology

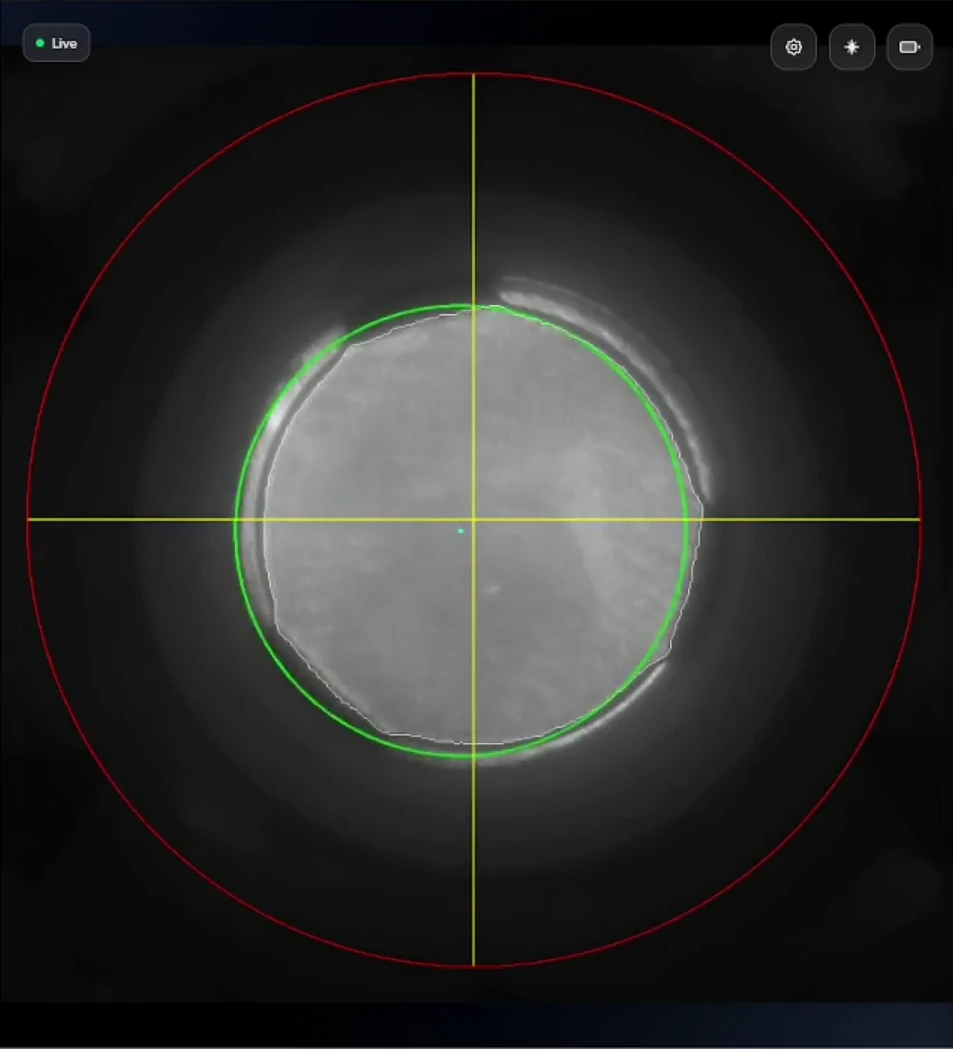

The STELA project focuses on the research and development of intelligent manufacturing solutions based on laser technology for sub-millimetre-level material processing. T...

Join Us at the XIX Workshop on Materials Processing with Laser Technology

We are pleased to invite you to the XIX edition of the Workshop on Materials Processing with Laser Technology, taking place on October 15 and 16, 2025, in O Porriño (Pont...

Invitation to Advanced Manufacturing Barcelona 2025 – Visit EXOM Engineering at Stand 1C29

Advanced Manufacturing Barcelona 2025 will take place on October 1–2, 2025, at Fira de Barcelona – Gran Via venue.We are pleased to invite you to this key industry event ...

Invitation to Visit Laser World of Photonics 2025 – Meet EXOM Engineering in Hall A2, Stand 329

Laser World of Photonics 2025 will take place from June 24–27, 2025, in Munich, Germany.We are happy to invite you to this leading industry event and would be delighted t...

13th Laser Anwender Forum (LAF) 2024

At the "13th Laser Anwender Forum (LAF) 2024" in Bremen, more than 100 interested participants will meet to discuss current topics, trends and visions for the future in t...

EXOM Engineering at MetalMadrid 2024

We look forward to seeing you on November 20 and 21, 2024, at booth No. 7F 06-08 in pavilion 7 of IFEMA, where we will present our laser welding and surface processing so...

The XVIII Laser Materials Processing Conference

We will participate in the XVIII Workshop on Materials Processing with Laser Technology, in O Porriño from October 16th to 17th 2024. Join us for a visit and let's explor...

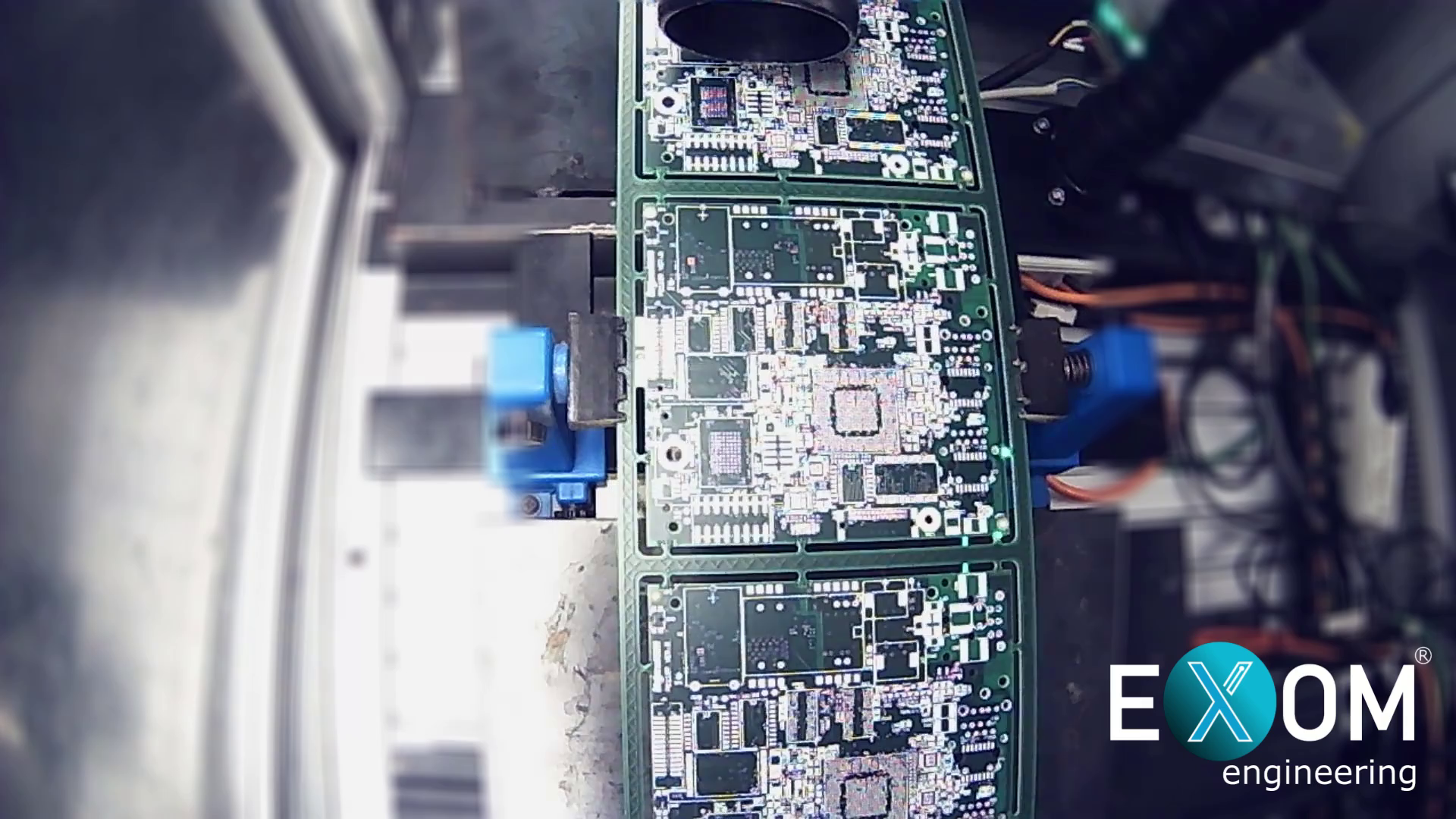

Pulsed green laser integration

PCB depaneling using green laser technology, combined with scanning optics, is a cutting-edge method for separating individual circuit boards from larger panels with high...

Informative note for Spanish companies seeking industrial laser solutions

Have you seen that laser machine with a very competitive price that performs exceptional welds? Are you involved in metal processing and have heard about the revolution t...

Innotech by Innobasque

Join us at BIEMH – International Machine Tool Biennial and register for the talks organized by Innobasque – Basque Innovation Agency, about innovative projects co-finance...