LASER WELDING FOR PRISMATIC CELLS

APRIL 11, 2024

Laser welding has emerged as a preferred method for joining busbars onto prismatic cells in battery module manufacturing due to its precision, speed, and reliability. However, achieving optimal weld quality requires careful adjustment of welding parameters. Among these parameters, the power intensity of the laser and the wobble geometry play crucial roles in determining the success of the welding process.

The power intensity of a single-mode laser refers to the concentration of energy delivered to the welding area. By adjusting the power intensity, we as machine manufacturers can control the depth of penetration into the materials being welded. For busbars on prismatic cells, finding the right balance of power intensity is essential to ensure adequate penetration without causing damage to the delicate components of the battery.

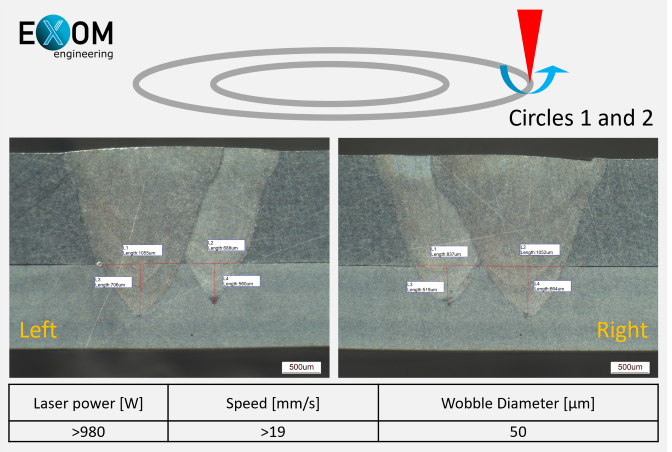

Additionally, the wobble geometry, which dictates the micro-movement pattern of the laser beam during welding, influences heat distribution and weld quality. By varying the wobble pattern, we can optimize the contact surface, reduce the heat input and minimize the risk of defects such as spattering or porosity. Experimenting with different wobble geometries allows for the identification of the most suitable pattern for achieving strong and reliable welds on prismatic cell busbars.

Finding the ideal parameter window for laser welding of busbars on prismatic cells requires a systematic approach. We do it through thorough testing and analysis, systematically varying power intensity and wobble geometry while monitoring weld quality and performance. Through iterative experimentation, the optimal combination of parameters can be identified, ensuring consistent and high-quality welds across production batches.

In conclusion, the power intensity of a single-mode laser and the wobble geometry are critical factors in optimizing the laser welding process for attaching busbars onto prismatic cells. By carefully adjusting these parameters and conducting systematic testing, we at EXOM Engineering can achieve robust and reliable welds, contributing to the overall performance and durability of your battery modules.